Find out more about

Lyophilization, or freeze drying, is a vacuum based drying process. A rapid drying stage preceeds the lyophilisation process. Freeze dryers utilize vacuum to sublimate the water content in a frozen product, meaning the frozen water is directly transformed into gas, skipping its liquid phase entirely. Sublimation ensures the most thorough, yet gentle drying. This complex process manages to completely dry the product, but preserve it’s characteristics and structure. The resulting products are of extremely high quality and very long shelf life. These benefits are quickly making lyophilization the ideal process for the food processing and pharmaceutical industries.

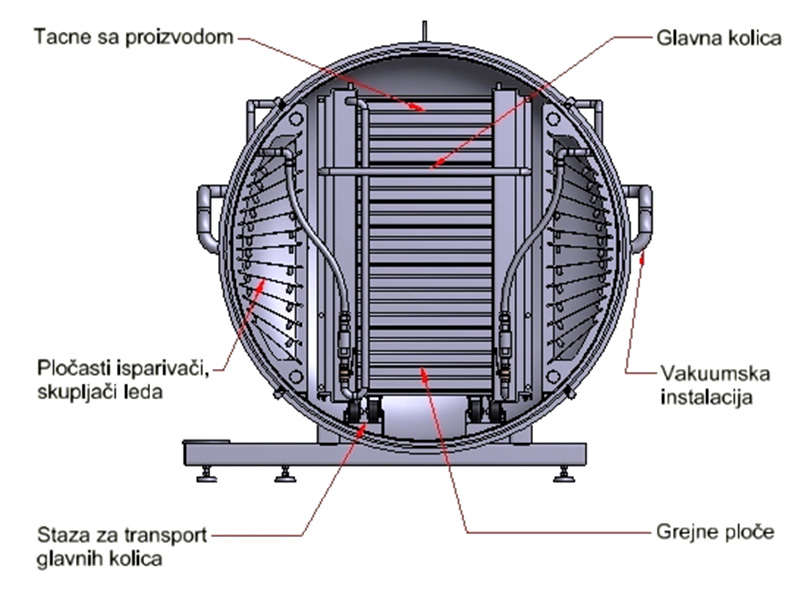

Our first offering in the field of ready to use freeze drying solutions is the MM 250, with a nominal capacity of 250kg of frozen products (fruits or vegetables). Our customers desires for larger capacity yet smaller sized machines required greater cooling and water vapor removing systems. Looking further from conventionally used copper pipe and radiator based solutions, our new generation of freeze dryers is equipped with pillow plate heating and cooling systems, a technology we proudly developed and refined in house.

The heating system is based on thermo fluid circulation.

PID temperature regulation of heating plates.

Heating plates are constructed of stainless steel ensuring optimal conductivity and needed ruggedness.

Inlet and outlet temperatures differ by less than 2°C.

Adjustable heating from 20°C to 110°C

Output of every plate is individually adjusted and balanced with valves.

Ensures that excess water vapor that isn’t immediately pumped out of the chamber condenses and is stored away from the product.

Innovative pillow plate technology forms the high-performance cooling and condensing system, keeping the chamber temperatures constantly cold and free of water vapor.

The system is compatible with freon, ammonia and CO2.

Defrosting after the process has finished is fast and seamless.

Quick to reach vacuums of <1mbar.

Precise vacuum sensors measure and control vacuum during the whole process.

Automated vacuum valves at all key points of the system keep the chamber pressures stable and reliable and pumps safe from any surges.

Integrated vacuum regulation through PLC makes sure that the system is working only when you need it, saving you valuable energy.

Circulation pumps for heating and cooling fluid are frequency regulated with PID, ensuring soft starting capabilities, lower energy consumption, quieter and longer life span of your pumps.

Real-time monitoring and regulation of vacuum.

Real-time monitoring of product temperature.

Industrial grade PLC with touch screen input allows for quick and easy changes to every step of the process.

We offer optional measuring equipment which allows real-time weighing of product during the process, giving you more information about current product dryness.

Freeze Dryer: MM 100 MM400 MM1000

Processing capacity (kg) 100 400 1000

Chamber diameter (mm) 1200 1800 2400

Chamber length 2m 3m 4m

Shelf dimensions (mm) 360 x 870 934 x 480 950 x 650

Number of shelves 40 112 228

Total shelf area (m2) 12.4 50 140

Heating area (m2) 28 104 292

We are available for all questions. Send us an EMAIL!

28. Juna 25, Belgrade